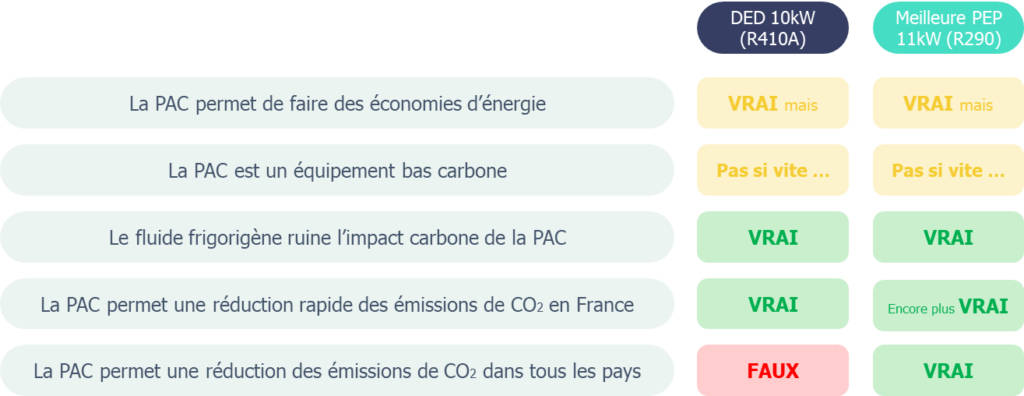

The heat pump, miracle low-carbon equipment? Here our True and false in 6 points

In partnership with

An excellent yield..

The main benefit of the heat pump is its efficiency. Thanks to the compression and expansion cycles of the fluid between the hot source (inside the housing at 21 °C – 69.8 °F.) and the cold source (outside air between -10 °C – 14 °F and 15 °C – 59 °F.), it is possible to capture “free” calories from the air or soil, while using a small amount of energy to circulate the fluid.

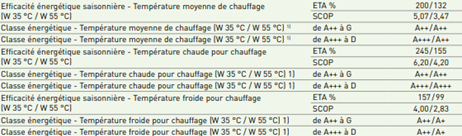

In optimal operation, that is to say with an outgoing water temperature of 35 °C – 95 °F for an air-water heat pump, its annual performance (SCOP or seasonal performance factor) can exceed 5 for the most efficient models: this means that the heat pump provides 5kWh of calories by consuming 1kWh of electricity to circulate the fluid. The same amount of heat provided by electric heaters would consume 5 kWh of electricity – with an efficiency of 1 for the joule effect.

The heat pump clearly reduces its final energy consumption for heating, whether as a replacement for electric radiators or a wood/gas/fuel oil boiler, with a yield ranging between 0.8 and 1.

… But also a variable yield

However, the heat pump is a paradoxical equipment: its efficiency decreases when the temperature difference between the hot source and the cold source widens. In other words, the colder it is outside, the less efficient the heating pump is, when it is most needed, so much so that it becomes preferable at a certain temperature to use additional energy to avoid excessive pressure on the heat pump.

It is also for this reason that the standards require manufacturers to provide SCOP values for 3 different climate zones:

· Hot: Athens

· Mild: Strasbourg

· Cold: Helsinki

For the same heat pump on the market, the SCOP can be 6.20, 5.07 or 4, depending on the zone. The colder the climate zone, the less benefit is provided by the heat pump in terms of energy savings. Extract from a heat pump data sheet (1)

And counterproductive qualities

Another advantage of the heat pump is its potential for reversibility: when the outdoor temperature exceeds the indoor temperature, it may be possible to reverse the cycle to extract calories from the indoor air.

If we introduce an active appliance in summer, to bring comfort to homes that did not necessarily use it before, we generate additional electricity consumption, especially during heat waves when the network is very sensitive!

Reversible heat pumps have therefore not been subsidized in France since 2018.

The heat pump is a low-carbon equipment. Not so fast…

The heat pump is often cited as a miracle device for energy transition, and benefits from significant tax incentives, as long as it is not also used to cool in summer.

The term “low-carbon equipment” can be confusing. Indeed, if we look at a heat pump; it is a heavy, increasingly complex, device whose manufacture, upkeep and maintenance have a significant impact, and which operates with refrigerant. It is important to set up a reference for comparison.

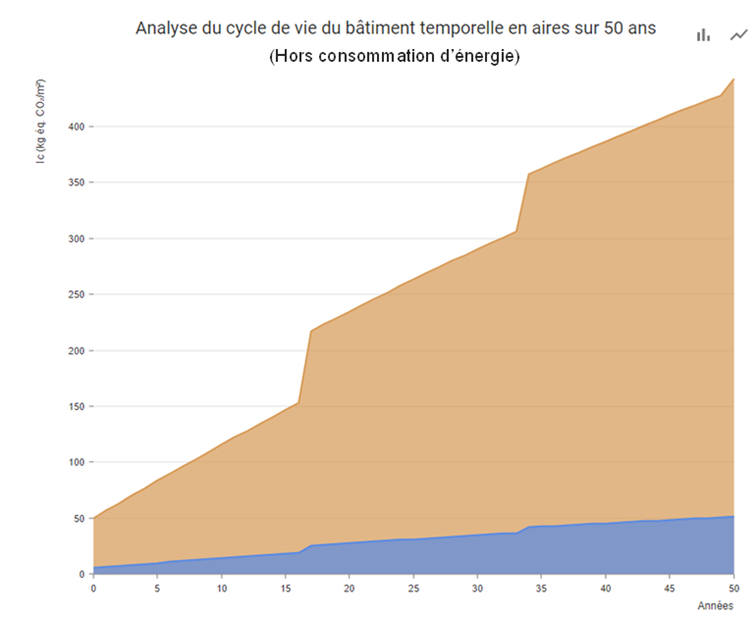

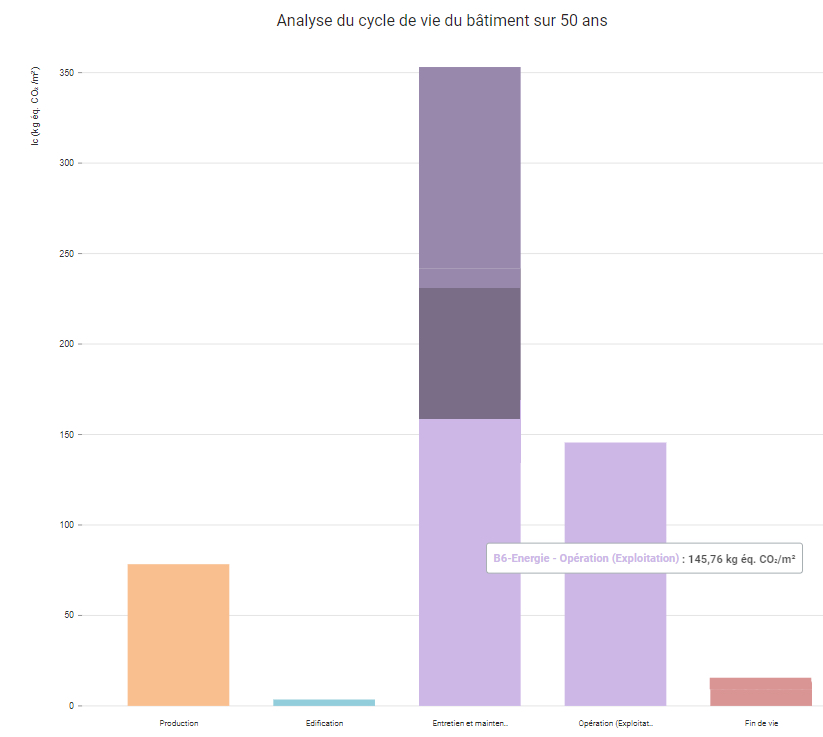

If we take, for example, the installation of an air/water heat pump and a gas boiler over 50 years, without considering the share of energy consumption, we obtain the following graph.

Temporal building cycle analysis over 50 years (excluding energy consumption)*

A comparison on the basis of the environmental impact of the equipment alone without modeling energy consumption does not confirm the relevance of the heat pump system.

In reality, it’s a matter of carrying out a complete Life Cycle Assessment (LCA), and analyzing whether the energy savings generated actually make it possible to amortize the rather heavy initial carbon footprint of the PAC equipment, compared with the existing system.

As for a refrigerator, the heat pump compresses and expands a fluid during successive operating cycles. The fluid used is usually a so-called “refrigerant”, which has a strong capacity to store heat thanks to the properties of molecular chemical bonds (carbon dioxide – CO2 – and water vapor – H2O – can also be used as refrigerants).

The most “efficient” fluids for this use are industrial gases, called “halogenated hydrocarbons”: HFCs, HCFCs, BFCs…, and the famous CFC (which became famous thanks to its ability to destroy the ozone layer with its chlorine atom), the this last one being banned since 1987.

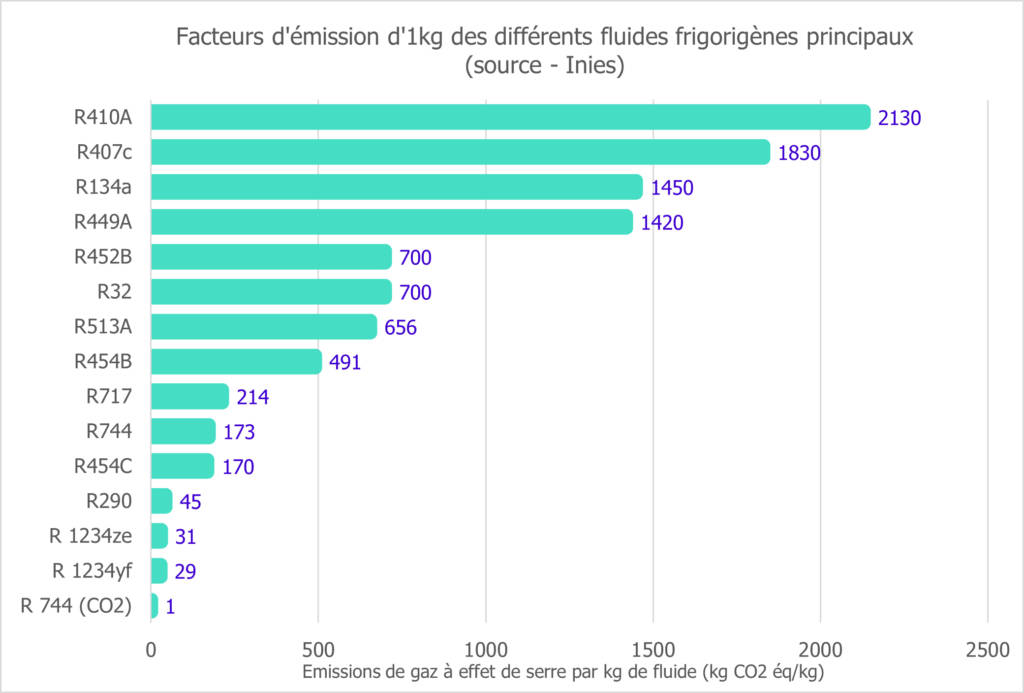

The more efficient a fluid is, the more its global warming potential increases, and in large proportions! The INIES database provides the CO2 equivalent emission factors for the most common coded fluids:

Emission factors for 1kg of the main refrigerants (source – INIES)*

Therefore, a single kg of R410A fluid lost in nature contributes up to 2 metric tonnes of CO2!

These fluids evolve in closed cycles in the heat pump. They are not supposed to disperse in the air. However, the seal is never perfect and in practice the entire impact of the fluid at the time of its leakage will be counted. The volume of fluid operated during loading and removal is therefore not taken into account during these operations.

The following specific rules (5) are considered for calculating the impact of the fluid for a heat pump:

· 2% leakage during its manufacture (module A3),

· 2% leakage per year during its working life, with a refill threshold value at 90% of the initial fluid load (module B1/B2),

· 10% leakage at end of life (module C4).

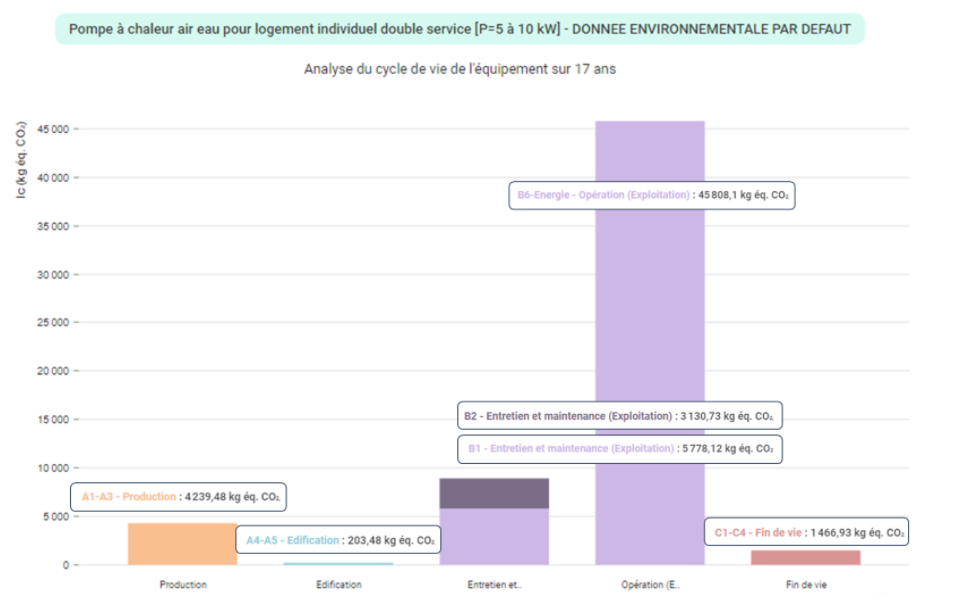

If we look at the values for the carbon indicator over the lifetime of our heat pump, excluding energy consumed over 17 years, the following breakdown is obtained:

LCA (global warming indicator) of the DED heat pump (static over 17 years)*

In the first place, we observe the preponderance of the maintenance phase (operation), that is to say modules B1 and B2, with a value of 8,908.85 kg CO2 equivalent (3,130.73 + 5,778.12); for a total impact of 14,818.74 kg CO2 equivalent.

These modules respectively represent the direct and indirect impacts of the refrigerant fluid on the operating phase, i.e. leaks. This means that even without taking into account the production / end-of-life of the fluid, the fluid, over the lifetime of the heat pump, represents 60% of its carbon impact* for the default data.

*To be more precise, this calculation does not include the leakage caused by the initial loading and the end-of-life removal, which is difficult to recover. By sticking to the rule of 2% and 10% of the total impact of the fluid loaded and removed, and assuming that the system is 100% loaded at the end of its life, this would mean an impact of around 66%.

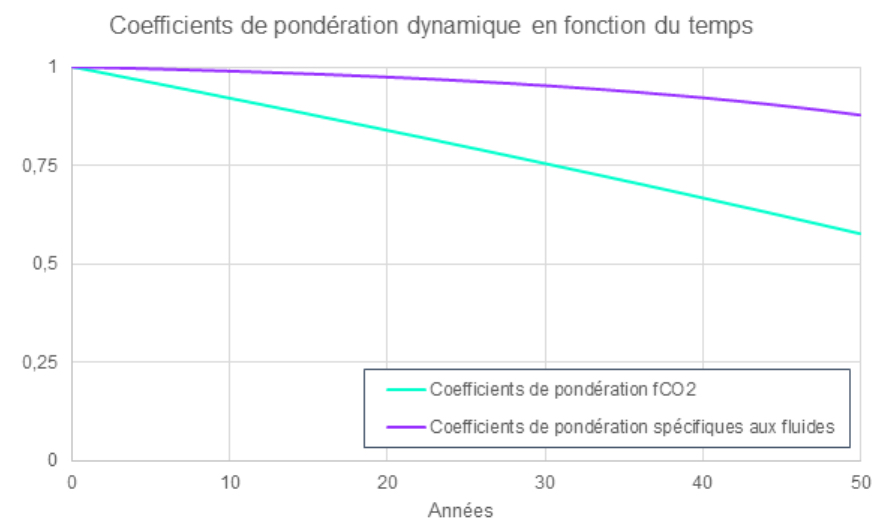

The result is even more pronounced in a RE2020 dynamic calculation, with the use of specific weighting coefficients for refrigerants. The graph below shows the respective evolutions of these coefficients:

Dynamic time weighting coefficient*

In our example, the heat pump works with R410A, the most impactful fluid with 2,130 kg CO2 equivalent of fluid. The R32 on the other hand emits 700 kg CO2 equivalent of fluid, or 3 times less. It is possible to significantly reduce the impact of a heat pump simply by acting on the fluid used.

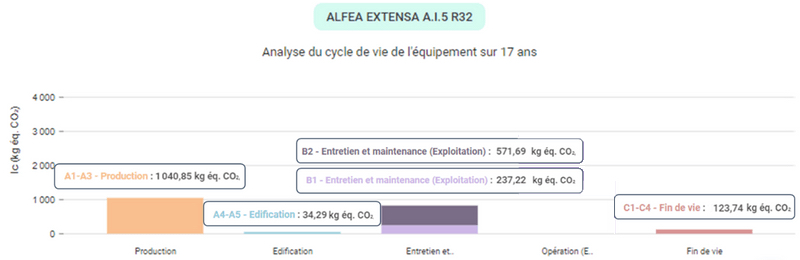

If we look at the Alfea Extensa A.I.5 heat pump made by the Atlantic group (6) for example, for the same power but with R32 fluid, the distribution of impacts over the lifespan of the equipment is as follows:

The modules B1 and B2 therefore represent 808.91 kg CO2 eq, for the whole equipment (excluding energy) of 2,007.79 kg CO2 eq, or 40% of the impact, and 11 times less than for the DED record.

NB: these figures should be put into perspective by taking into account the consumption of the heat pump. Here we recall that consumption is considered only in terms of a system and not of a piece of equipment. Indeed, the same equipment can for example be installed in use and in backup and therefore have almost zero consumption for one and very high consumption for the other. It is the sum of the two that matters.

The heat pump allows to rapidly cut CO2 emissions in France. TRUE

As stated before, even if a heat pump alone has a significant carbon weight, this information alone is not sufficient to discredit it from an environmental point of view. It is necessary to take into account the impact of the energy consumed to compare it with other systems.

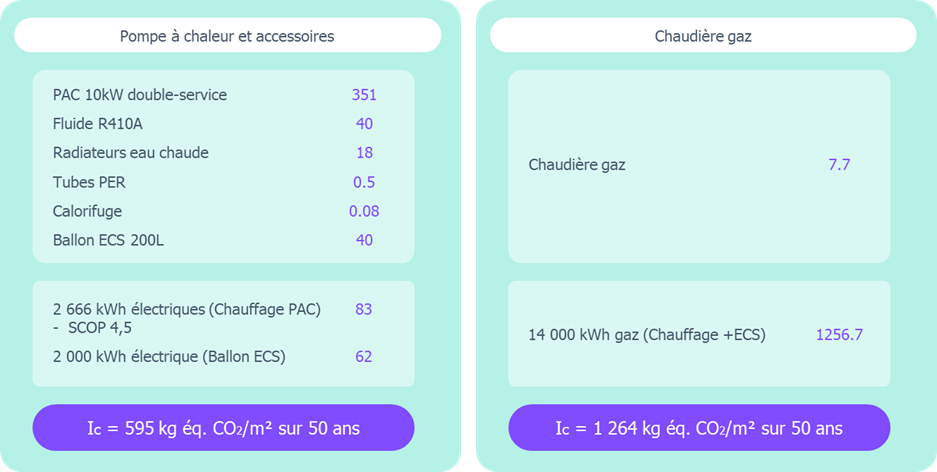

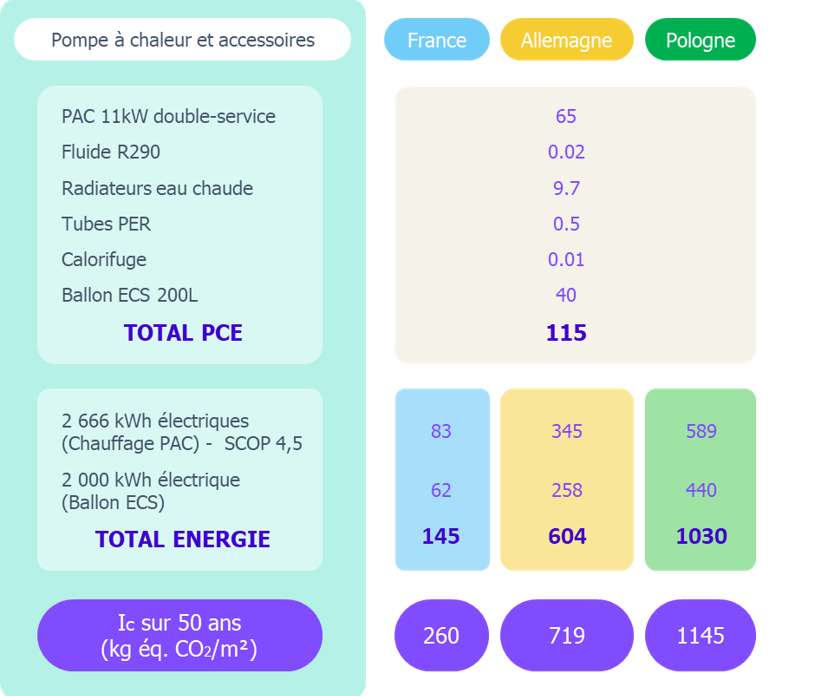

For our analysis, we took the most common example which is covered by tax incentives, namely the replacement of an old gas boiler by a new heat pump system. To make the most of the heat pump, we consider a complete replacement of the terminals with radiators to operate the heat pump at low temperatures, where its performance is best.

We therefore compared a complete system [heat pump + networks + terminals + power consumption] with a simple boiler replacement [gas boiler + gas consumption], (the existing terminals being considered still functional), in our 100 m² house, located in Colmar, still using DED records.

Considering a need of 14,000 kWh for heating, including 2,000 kWh for DHW, we therefore compared the systems over a period of 50 years:

This modeling allows us to obtain the following LCA for the heat pump variant, this time with the module B6 (energy consumed) calculated in front of the equipment system. To summarize, there is a rapidly significant gap between the gas boiler system and the heat pump!

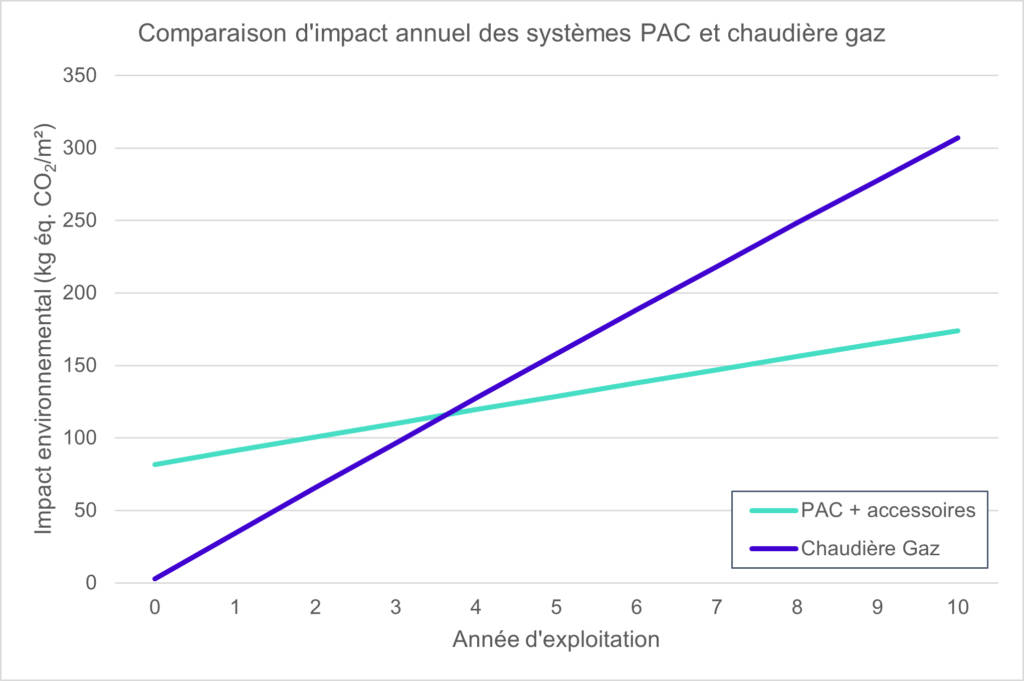

With a comparative analysis on the first 10 years in Nooco, we find that the heat pump system becomes profitable in terms of CO2 within only 3 and a half years.

This model confirms that the share of energy is significant. Nevertheless, and contrary to common beliefs, the share of energy is clearly below that of the fluid once the choice of the heat pump is made (therefore electrical energy).

The heat pump is a low-carbon equipment. FALSE

As our house is in Colmar (French city), so not very far from Germany, we wondered what it would be like if we crossed the Rhine (river) to install the same heat pump, in identical climatic conditions.

In France, the final electricity emission factor is among the best in Europe, with 79g CO2/kWh equivalent consumed.

This factor is a weighted average of the impacts of all sources of electricity production over a year: about 12 g CO2 equivalent for nuclear, 45 g CO2 equivalent for solar power, 490 g CO2 equivalent for gas…, as well as the share of imports.

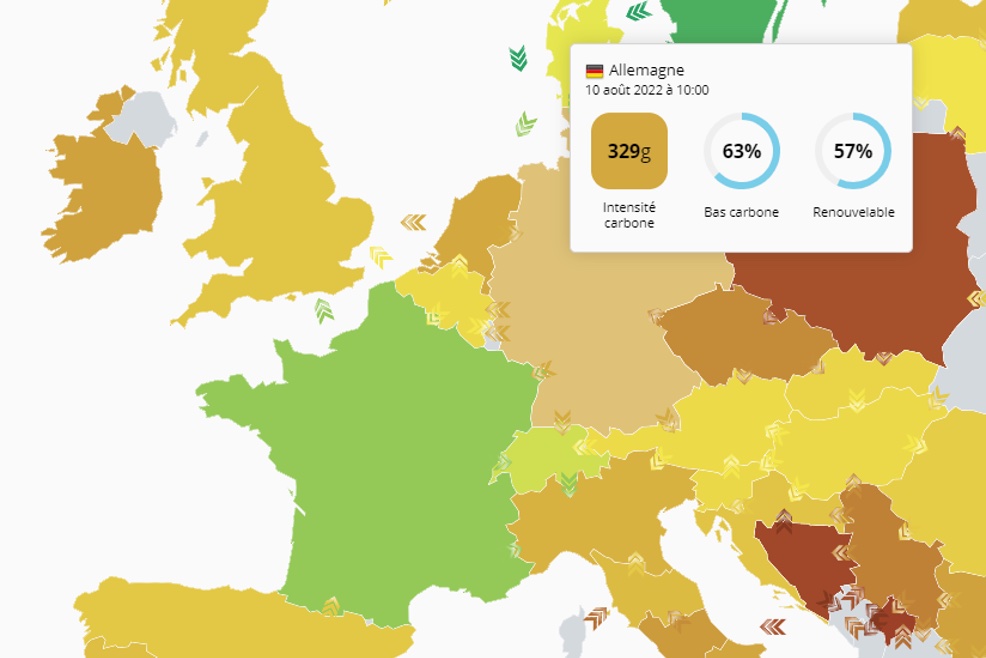

At the time this article was written, we could see on the Electricitymaps website that the emission factor of the electric kWh consumed in Germany was much higher with 329 g CO2/kWh eq consumed. Indeed, despite a high renewable energy capacity, the significant proportion of coal (emission factor of 820 g CO2/kWh eq consumed) in the electricity mix weighs heavily on the average German emission factor.

Thus, by a quick calculation that multiplies the impact of the electrical consumption of the heat pump system by 4.16 (EF Germany/ EF France = 329g CO2 eq / 79 g CO2 eq = 4.16), taking the French carbon weight of 595 kg CO2 equivalent to a German one of 1053 kg CO2/m² eq, not much less than the gas boiler replaced…

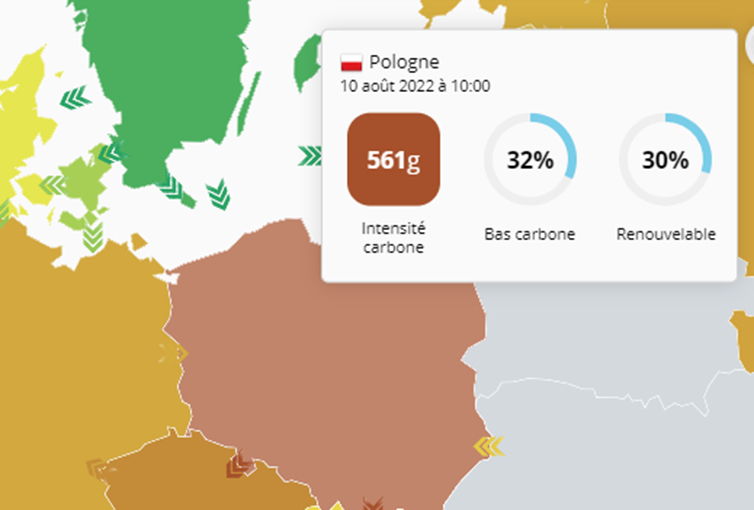

Using the same simple calculation, this reasoning is applied to Poland, which emits 561 g CO2/kWh eq electricity consumed, 1,479 kg Co2/m² eq would be reached, well above our gas boiler!

We understand from these examples that the relevance of a heat pump to reduce the carbon impact (in the same climate zone) is directly linked to the distribution of the electricity mix of the country where it is installed.

In France, Switzerland and Scandinavia, it clearly makes sense, but elsewhere in Europe, it is necessary to look at the country’s electricity mix.

However, in this period of gas scarcity as a source of heating energy, the carbon weight is not the only indicator to be taken into account. Helping to reduce the consumption of fossil fuels through electrical appliances makes sense, as long as electricity production is not itself powered by gas and coal.

All heat pumps are equal in reducing CO2 emissions. FALSE

To simplify, we based our analysis on a DED air-water heat pump available on INIES. It is supposed to be representative of heat pumps on the market, but incorporates safety factors aimed at making it a premium product, in order to encourage manufacturers to offer even less impactful products.

Several levers exist to reduce the environmental impact of a heat pump, including:

· Using a lower-impact refrigerant fluid,

· Reducing the mass of the equipment,

· Using recycled metals (See Nooco article on the steel ventilation duct)

A number of manufacturers have played along, and an increasing number of equipment have a Product Environmental Profile (PEP), which estimates the environmental impact of 27 indicators, and is verified by an external third party.

A PEP record is an individual or collective record produced by a manufacturer or a manufacturers’ union. It contains environmental data on a piece of equipment or a type of equipment.

In Nooco, for each equipment, you can consult all the certified products (with a PEP record) in order to pinpoint each product in relation to the major data (excluding power consumption).

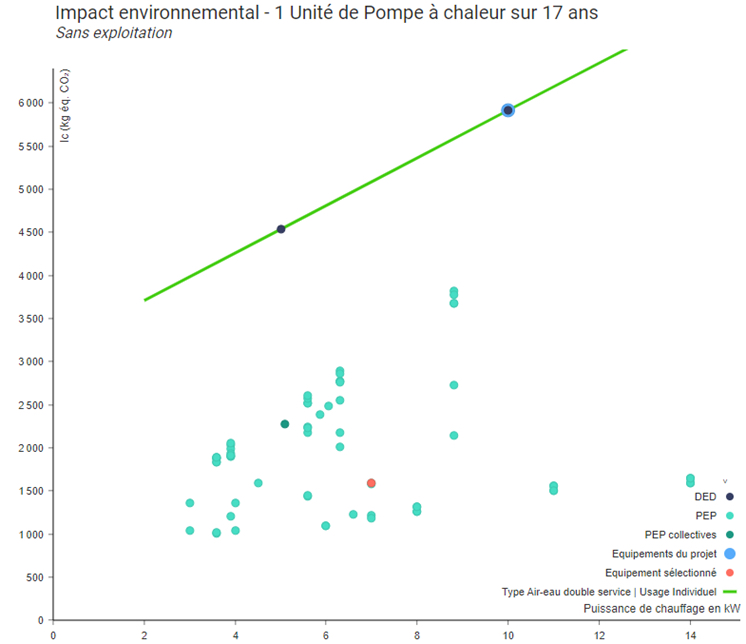

For the heat pump, we find the following graph with the global warming contribution indicator on the y axis and the power in kW on the x axis.

Each point represents a record from the Inies database. The dark blue dots correspond to the default data (DED), together with safety coefficients. Green dots represent real market products (PEP)

We can immediately see that the differences in impact are significant: -50% for the average of heat pumps around 5.5 kW, and up to -75% for the best performing products!

By selecting the 11kW heat pump, with the lowest impact, which has a SCOP of 4.5 °C (39.2 °F) to 35 °C (95 °F), we reduce the impact of our typical project from 595 to 260 kg CO2/m² eq (also selecting the best PEPs for the other components).

With the best PEP records selected, the heat pump system even allows a reduction in CO2 emissions in Poland, compared to a gas system, but the difference remains slim.

Under these conditions, our true/false analysis needs specific changes:

(1) GAMME AQUAREA ALL IN ONE HAUTE PERFORMANCE R32 GENERATION J, KIT-ADC03JE5,

(2) A Default Environmental Data (DED) corresponds to a generic data set established by the French government, which takes into account safety coefficients. It does not represent a specific product, but a penalizing upper limit of impact for the equipment studied.

(3) Ic corresponds to the climate change impact indicator, measured in kg CO2 eq. and obtained using the dynamic LCA calculation method. Dynamic, as opposed to static, refers to an LCA calculation method in which greenhouse gas emissions are weighted according to their year of emission, in order to take better account of the effects of time on impact.

(4) 50 years corresponds to the lifespan of a building set by the RE2020, the reference period for an LCA study of a building..

(5) PSR – Specific rules for electric compression thermodynamic generators providing space heating and/or cooling and/or domestic hot water production: http://www.pep-ecopassport.org/fileadmin/user_upload/PSR-0013-ed2.0-FR-2019_12_06_.pdf

(6) ALFEA EXTENSA A.I.5 R32 (v.1.1) (id Inies : 30787)pour une puissance de 10kW